Right-Size Your Automation Investment

Every dollar invested in a modern warehouse or distribution center these days must work harder, faster, and smarter. With tighter margins and intense competition, the pressure to realize the return on investment (ROI) for every piece of automation equipment and every square foot of space is immense. Making the decision to automate with a Goods-to-Person (G2P) system is one of the most significant capital investments a company can make—a multi-million dollar bet on future efficiency, speed, and growth.

But what if the full potential of that investment is unknowingly left on the table from day one? Foundational decisions about system size and configuration are sometimes based on estimates and historical averages, leaving operators to wonder if they’ve overspent on a system that's too large or, worse, too small, which would limit future demand growth. The core challenge is clear: how can you guarantee you are right-sizing your automation investment realizing the value after deployment?

By combining the world-class AutoStore robotic storage solution from Kardex with Paccurate's advanced Packing Control System, we’re fundamentally changing the financial outcome of a warehouse automation project, ensuring a predictable, high-return on investment.

The “Problem” with Traditional System Sizing

Historically, sizing an AutoStore grid has been a process rooted in approximation. Relying on broad cubic SKU velocity assumptions—essentially, educated guesses about the average volume of items, how many to store at any one time, and how quickly they move can be fraught with error. The cost of half an inch can add up quickly.

The first risk is over-investing. By failing to account for how items actually fit together inside a bin, traditional methods often overestimate the required number of bins and the corresponding grid infrastructure. This leads to a larger-than-necessary capital expenditure. Every extra dollar spent on underutilized bins and grid space is sunk capital yielding zero return, a permanent drag on the project's overall ROI.

The second, and often more costly, risk is under-building. A system designed too small, based on overly optimistic fill-rate assumptions, quickly leads to operational chaos. Bins fill up faster than anticipated, forcing frequent and labor-intensive manual consolidation tasks. This creates operational bottlenecks, reduces throughput, and can bring the entire system to a halt, actively destroying the very efficiency the investment was meant to create. This scenario inevitably forces a premature and costly expansion, reducing the original ROI projections.

How do we fix it?

Maximizing Asset Utilization with Precision

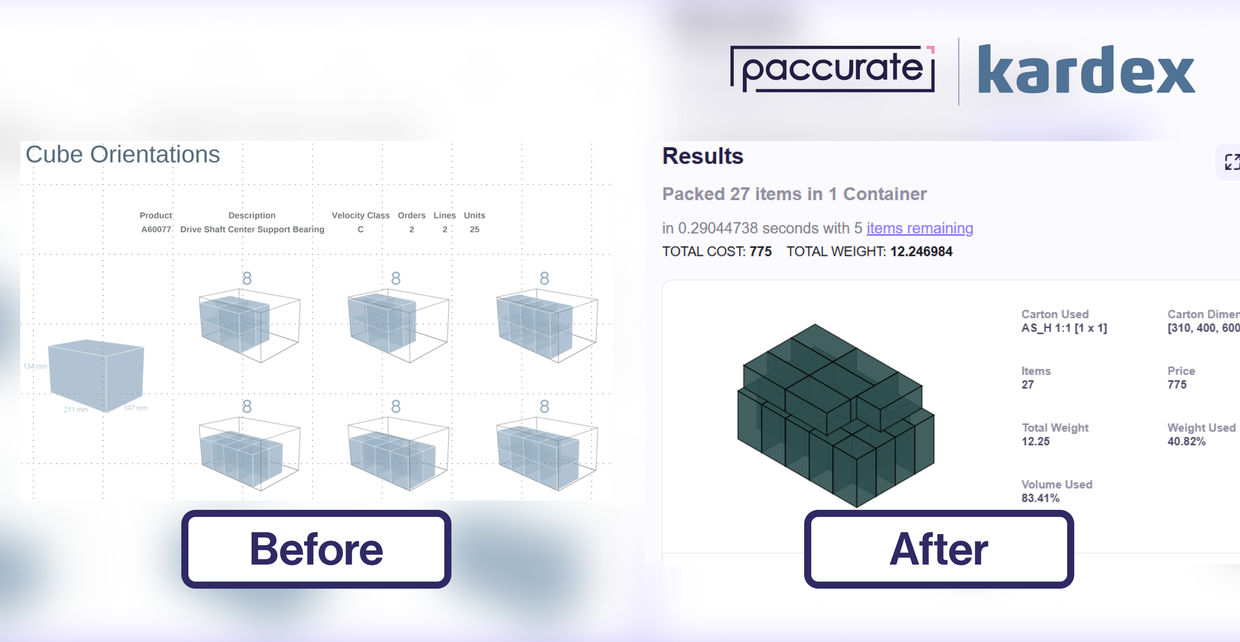

To close this gap, Paccurate and Kardex collaborated on two extensive analyses to prove the financial impact of replacing approximation with algorithmic precision. Using Paccurate’s advanced cubing engine, the teams demonstrated how applying smarter cubic optimization can help prevent oversizing an AutoStore system in the first place while also providing tools to better maximize grid utilization once live.

Case 1: Standard Loose SKU Grid Sizing

The first analysis the team investigated was an apples-to-apples comparison of 3D cubing vs. the standard cubic velocity approach. Even in this simplistic analysis, by using actual item-level cubic optimization the team discovered a 5% decrease in total bins required. It was estimated that additional savings could be found if item-level SKU geometry was taken into account as well.

This isn't just a minor efficiency gain; it represents a direct, upfront reduction in capital expenditure. That 5% is capital that can be re-allocated to other high-value projects or simply saved, immediately improving the project's ROI before the system even goes live.

Case 2: Advanced Optimization for a 19% Leap in Density

The second analysis revealed an even more powerful strategy for maximizing ROI. Instead of just optimizing how items fit into a bin, the team used Paccurate to optimize the size of master packs before they were stored.

By redesigning master cartons to have higher volume utilization and be sized with standard AutoStore bins in mind, the system could store more cases per bin. This two-step optimization process unlocked a massive 19% increase in bin utilization. This level of density allows for a significantly smaller grid footprint, dramatically cutting initial capital costs. It also maximizes the return from the initial build-out by increasing the storage capacity of the entire system, deferring the need for future expansion and the associated costs for years.

Protecting Your ROI: Slashing Hidden Operational Costs

The financial benefits don't stop once the system is built. Integrating Paccurate’s technology into the daily workflow protects and enhances the system's ROI by tackling hidden operational costs that quietly erode profitability.

Eliminates Costly Downtime: A common operational headache is unexpectedly running out of bin space during receiving, which can halt induction processes. Paccurate’s patented cartonization engine, PacAPI’s, intelligent logic can be integrated to systematically allocate incoming inventory to the most optimal bins, preventing space shortages and ensuring the expensive automation asset is always productive, not sitting idle.

Cuts Non-Value-Added Labor: Without precise packing logic, operators spend countless hours on manual, non-value-added tasks like consolidating bins to free up space. Paccurate determines the optimal packing configuration at the point of induction, drastically reducing this wasted labor. This allows you to reassign personnel to revenue-generating activities, directly improving your operational expense ratio.

Unlocks Future Throughput Gains: The data provided by PacAPI opens the door for even more advanced, real-time optimizations. An AutoStore system could potentially make smarter decisions on where to store bins based on dynamic data, reducing robot travel time and increasing overall throughput. This ensures the system consistently operates at its peak, delivering the maximum possible return year after year.

The strategic integration of Paccurate's optimization algorithms with AutoStore powered by Kardex is more than a technical improvement. It ensures major capital expenditure becomes a precision and data-driven investment guaranteed to deliver maximum value.

Learn more about our partnership with Kardex.