What is a Packing Control System (PCS)?

Perfect packing is harder than it seems. Despite major investments in automation, packing remains one of the least controlled parts of fulfillment. Operators face constant changes in SKUs, materials, and carrier policies, but often lack the tools to keep up. Boxes and mailers are the only tangible output of even the most automated fulfillment centers, yet the software that determines these is often a limited feature or point solution that’s difficult to manage.

When packing responsibilities are split across departments, efficiency and cost control can fall through the cracks. And even when advanced cartonization software algorithms are deployed, adjusting packing behavior or aligning with automation changes can be slow, complex, and expensive.

As transportation and material costs continue to rise, tariffs hurt margins, and consumers become dramatically less tolerant of waste, a new paradigm is required.

What Is a Packing Control System (PCS)?

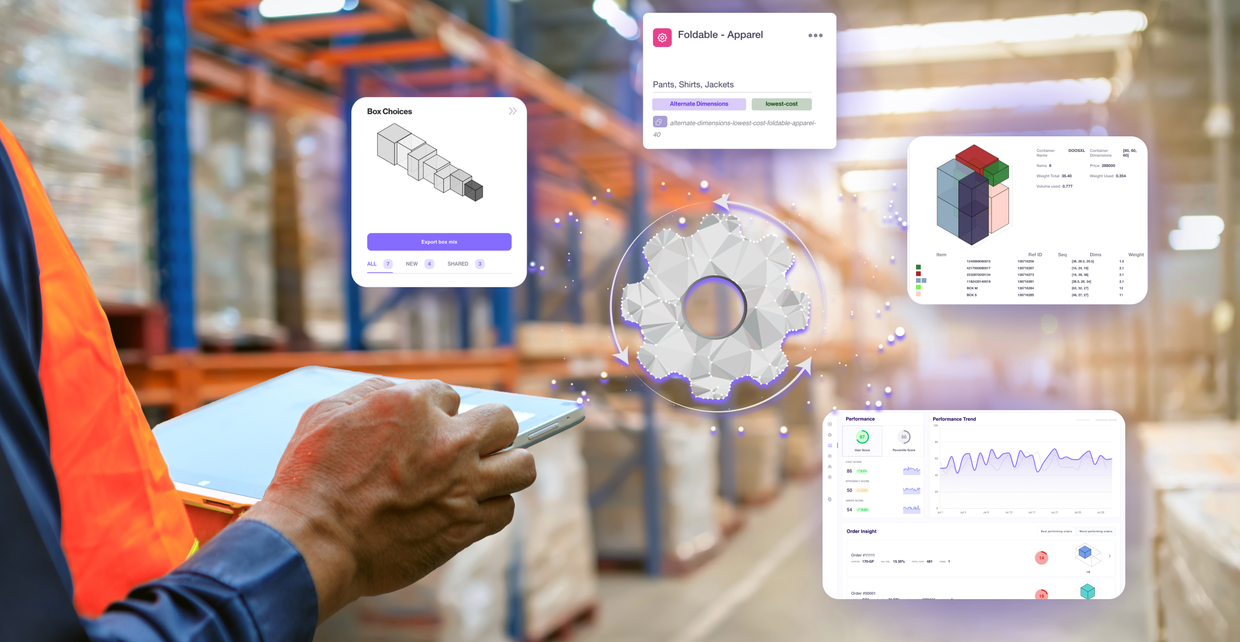

A new category of fulfillment software, a Packing Control System, gives shippers complete visibility and control over how every order is packed. Sitting alongside Warehouse Management System (WMS), Warehouse Execution System (WES), and Transportation Management System (TMS), a PCS serves as the dedicated system for everything related to packing and packaging, bringing together cartonization, simulation, monitoring, and management.

It includes everything you’d expect from packaging optimization software, but expands it into a full control layer that unifies these functions into a single system.

Fast cartonization, or “cubing,” is table stakes in 2025. But when speed alone isn’t enough, the algorithm behind each packing decision needs to understand what it’s optimizing for and the cost impact of every choice. A PCS accounts for carrier rate incentives, material costs, and even customer preferences automatically, ensuring every packout decision balances cost, performance, and compliance.

A PCS is automation-aware. It can determine, in real time, whether an order should be routed to a Packsize machine or an autobagger, coordinate item delivery from an automated storage and retrieval system (ASRS) to support the most efficient packing flow, and even optimize box selection for AMR shelves.

Beyond execution, a PCS delivers visibility into how packing decisions affect the business. Packing and Packaging efficiency, and sustainability are now measurable KPIs impacting both compliance and customer loyalty. With a PCS, shippers gain actionable insights into material usage, waste, and shipping trends, highlighting high-impact SKUs and opportunities for improvement.

And because fulfillment never stands still, packing logic can’t either. A PCS enables operators to adapt quickly, testing and deploying new packing rules directly without putting the burden on IT or requiring backend code changes.

Why the Paccurate PCS Is the Industry’s First

Paccurate created the industry’s first Packing Control System (PCS) to give shippers complete control over packing. At its core is a cost-aware cartonization engine that optimizes parcel packing based on materials, labor, and carrier rates rather than cubic volume alone.

The system allows teams to test packing and packaging strategies, at scale, before implementation, such as adding a new box size or introducing an on-demand packaging machine. Operators have a hands-on environment for creating and adjusting packing logic without touching backend code, giving them the agility to move quickly.

Paccurate PCS also provides continuous visibility into packing performance, including costs, material use, and efficiency, enabling ongoing data-driven improvement.

Together, these tools create a unified system that empowers shippers to control, measure, and continuously improve how every order is packed.

Packing Optimization Real-World Example

Retailers such as Altitude Sports have quickly seen measurable results after implementing Paccurate’s Packing Control System. At the heart of their success is PacAPI, which determines the ideal packing configuration for every order based on item dimensions and custom rules. These rules ensure that SKUs with specific characteristics, whether fragile, foldable, or compressible, are always packed appropriately.

With PacManage™, the newest customer-centric product in the Paccurate PCS, Altitude Sports gained the flexibility to create, test, and update rules directly in the platform without changes to back-end code.

After launching Paccurate PCS:

Fill rates increased by six percent

Mailer utilization rose from sixty to seventy-eight percent

Training time for new packers was reduced by fifteen percent.

Beyond operational efficiency, Paccurate helped Altitude Sports minimize wasted space inside packages, reducing corrugate use, which aligned with their sustainability goals.

The Future of Packing Control in Fulfillment

Before warehouse management systems, inventory tracking was manual. Today, a WMS is indispensable to nearly every operation. Packing is facing the same evolution. If pack out strategy has been left behind, a Packing Control System helps restore the visibility and control that legacy cartonization software can’t provide.

When teams have direct control over packing logic through a PCS, costs are reduced, sustainability goals are achieved, and operations become more resilient. Just as WMS transformed inventory management, PCS is transforming how fulfillment teams think about packing.