Welcome to the Paccurate Blog

The Truth About Dimensional Data and Packing Efficiency

Nearly 50% of warehouses lack accurate SKU dimensions. Learn how dimensional data accuracy drives packing efficiency, reduces costs, and improves fulfillment operations.

Read The Article

December 4th, 2025

Building a Better Packaging Lineup: Choosing the Right Mailers for Cost and Efficiency

Complete guide to poly, kraft, and padded mailers for fulfillment. Learn how mailers reduce costs, improve efficiency, and optimize packaging lineups.

Read the Article

December 2nd, 2025

Paccurate Named to Inc.’s 2025 Best in Business List in Best Social Good

Paccurate earns a spot on Inc.’s 2025 Best in Business list for Social Good, highlighting its impact on waste reduction and sustainable supply chain practices.

Read the Article

October 31st, 2025

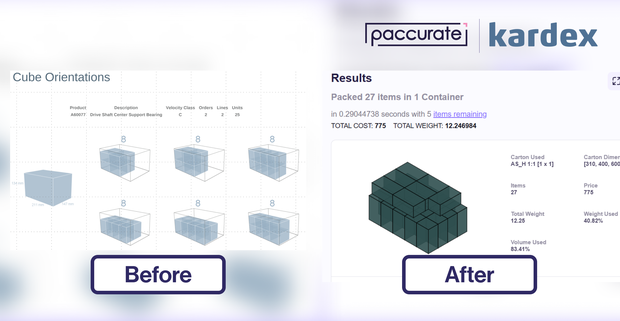

Right-Size Your Automation Investment

Don't risk your AutoStore ROI with the wrong size solution. Paccurate and Kardex partner to ensure the right-size solution, maximizing efficiency.

Read the Article

What is a Packing Control System (PCS)?

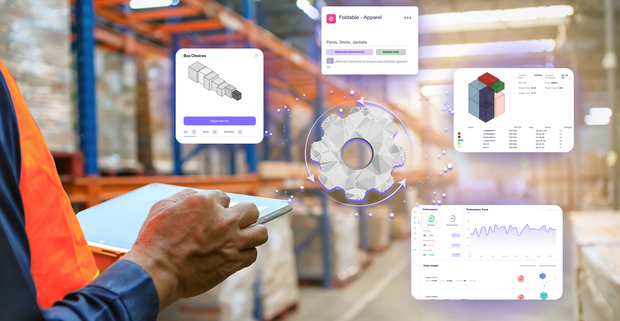

Perfect packing is harder than it seems. Despite major investments in automation, packing remains one of the least controlled parts of fulfillment. Operators face constant changes in SKUs, materials, and carrier policies, but often lack the tools to keep up. Boxes and mailers are the only tangible output of even the most automated fulfillment centers, yet the software that determines these is often a limited feature or point solution that’s difficult to manage.

Read the Article

Paccurate Introduces Resources: The Control Center for Packing Logic

Paccurate, the leader in cost-aware cartonization, announces Resources, a powerful new feature within the Paccurate Packing Control System (PCS) that streamlines implementation and puts packing control directly in the hands of operators. By centralizing box types, packing rules, and carrier rates in one dashboard, Resources accelerate Paccurate deployments by 3-5 weeks while making it easy for operators to manage complex cartonization logic across multiple facilities and customer accounts.

Read the Article

Paccurate Processes 1 Billion Packs

Lessons from Building the First Packing Control System

Read the Article

Is Your Packout Ready for Peak?

Peak season prep is in full swing. You've got new automation moving, your warehouse systems are running smoothly, and inventory is staged and ready for an influx of orders. However, here's the thing that most operations teams miss: they spend months perfecting everything upstream and then overlook the pack station.

Read the Article

A Packing Terminology Guide: Terms Shippers Need to Know

The supply chain and logistics industry has its own language, packed with acronyms, jargon, and terms that aren’t always clearly defined. When it comes to packing, understanding the right terminology can make a big difference in how efficiently and cost-effectively you manage your operation.

Read the Article